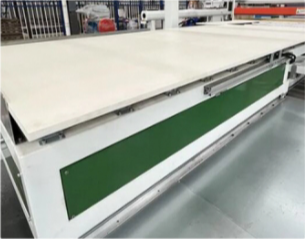

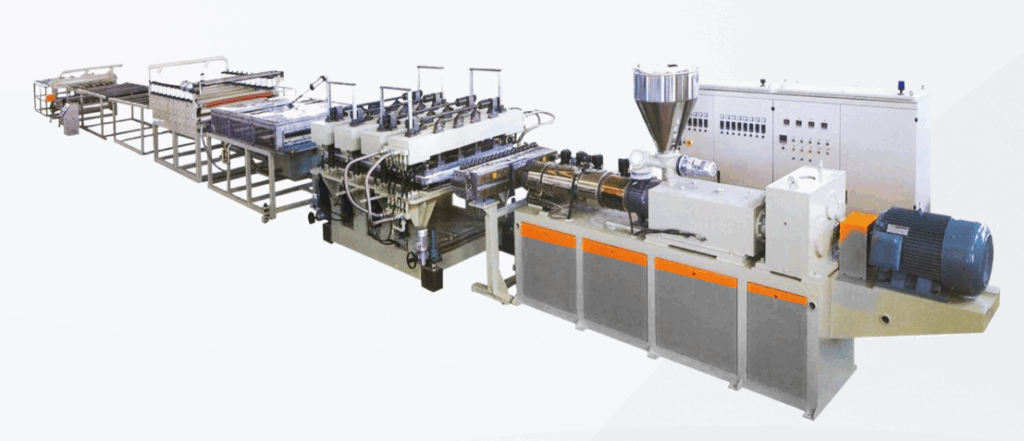

This production line is designed for manufacturing high-quality PVC and WPC foam boards. It consists of an extruder, mould, calibrating platform, cooling frame, haul-off machine, cutting unit, and stacker.

The system also supports A+B+A three-layer co-extrusion by adding an additional extruder and distributor, enabling enhanced board strength and cost efficiency.

For optimal performance, the line can be equipped with a water chiller to improve cooling capacity and increase overall production efficiency.

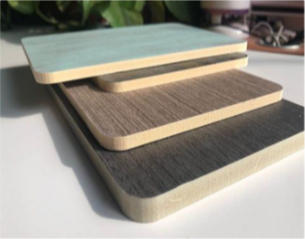

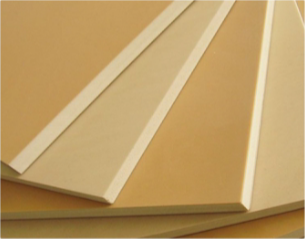

The finished boards are lightweight, durable, and widely used in furniture, construction, advertising panels, and interior decoration.

| Model | SJSZ80/156 | SJSZ92/188 |

| Extruder | SJ80/156 | SJ92/188 |

| Width | 1220 mm | 1220 mm |

| Thickness | Up to 25 mm | Up to 35 mm |

| Max Capacity | 350 kg/h | 350 kg/h |