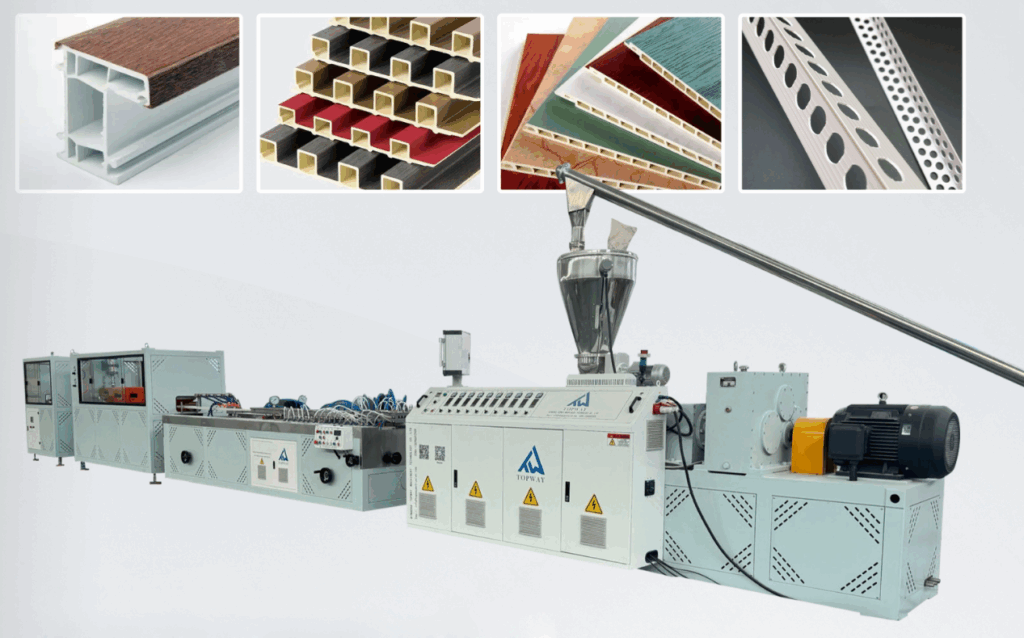

This PVC profile extrusion line is designed for manufacturing a wide range of PVC profiles, including window frames, door frames, ceiling and wall panels, cable trunking, skirting boards, and other construction materials.

Using PVC blended with calcium powder, wood powder, and other additives, the line ensures high-quality, durable, and versatile products. Advanced temperature control is achieved through digital PLC systems or manual control meters, ensuring reliable performance, high extrusion efficiency, and easy maintenance.

Machine Composition

The production line typically includes a Conical Twin-Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, and Stacker. By using different molds, it can produce a wide variety of UPVC profiles, such as:

- Window and door profiles

- Wall and ceiling panels

- Window sills, cabinet doors, curtain boxes

- Cable ducts, trunking, skirting boards, protection corners

Additionally, with customized screws and molds, it can also produce WPC (Wood-Plastic Composite) products, such as WPC wall panels and WPC window profiles.

Key Benefits of PVC Profiles

- Fire-resistant and self-extinguishing

- Resistant to insects, termites, rot, and rust

- Withstands weather and chemicals; waterproof and washable

- High rigidity and impact resistance, no peeling

- Authentic natural wood texture for enhanced appearance

- Easy to cut, drill, nail, saw, and rivet—ideal for DIY use

- Requires minimal maintenance, no painting needed

- Fast and simple installation reduces labor and costs