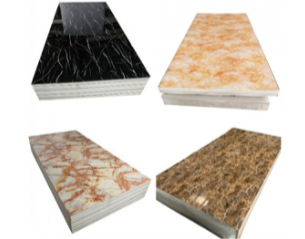

The PVC plastic marble board production line is a specialized system for producing high-quality decorative panels using PVC compounds. These boards combine an extruded base layer with a marble-texture film, creating a durable and elegant material that closely resembles natural stone.

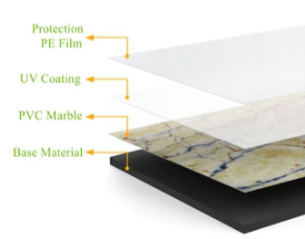

Through a three-roll calender process, the film and base layer are hot-pressed into a seamless composite, ensuring:

- Smooth and glossy surface finish

- Strong adhesion without delamination

- Non-toxic and environmentally friendly properties

- Resistance to deformation without the need for paint

As a modern decorative material, PVC marble boards are increasingly popular in international markets due to their cost-effectiveness, reduced reliance on natural resources, and alignment with updated consumer preferences.

They are widely used in interior decoration, wall panels, ceilings, furniture, and commercial spaces.

Production Process

- Raw Material Preparation – PVC powder and additives are mixed.

- Feeding – The blended material is fed into the extruder.

- Extrusion – Processed by the SJSZ 80/156 double-screw extruder through the mould.

- Lamination – Marble-texture film is applied and laminated using a three-roll calender.

- Cooling – Boards are cooled with group rollers to stabilize shape and surface.

- Haul-Off – Continuous pulling ensures smooth movement of the sheet.

- Cutting – Transversal cutter and edge cutter trim the boards to required sizes.

- Conveying – Boards are transported via conveyor for final processing.

- Surface Treatment (Optional) – UV coating for enhanced durability and gloss.